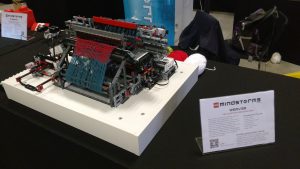

My Weav3r loom and I were invited to exhibit at the MINDSTORMS booth at LEGO World 2017 this year – what a blast!

I had a deadline of the end of January to get the loom built and mainly functional in order to get it shipped out to Denmark. So, lots of hours in my attic across New Year, and coding in the last week of January to get it ready. One thing I did learn is that LEGO axles that need to slide, as opposed to rotate, do not mix well with traditional English Christmas cake! I managed to get icing on the axles which then turned into adhesive goo, preventing the heddles from setting – oops!

I was so glad that it worked after being transported. I had packed it with a very large amount of bubblewrap, and the only thing that had dismantled was part of the heddle selector’s gear rack. Here’s a video of it working on Day 1:

This was the first time it had actually woven anything of any length, so I was still learning how the machine would actually run. You can see in the video that the wefts are quite spread out in places. That’s due to the cloth wind-up drum running at a constant angular velocity, so as the day ran on the cloth would wind faster and faster. This lead to me altering the programming before breakfast on Day 2 🙂

The change to the programming allowed me to alter the angular rate of the winding reel throughout the day. This meant that as the scarf got longer I could slow it down, keeping the weft spacing in good order.

Here’s a video of it running on Day 3. This is an attempt to show how the “Jacquard” part of it works. There is a selector that can move along the 32 heddles and set a pair of pins, to the front or back, to set which ones go up or stay down. The video is not as clear as I’d like so I shall shoot another soon:

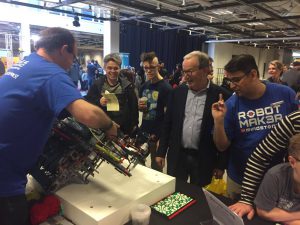

Unfortunately the loom stopped working towards the end of Day 3. It ceased to be able to align correctly, resulting in the heddle lifter arm jamming up. This happened just before the Owner of LEGO turned up:

Fortunately for me he’d seen it working a few minutes before – phew!

On investigation for the rest of the afternoon, and the next morning it appears that one of the motors wasn’t functioning correctly:

On Day 4 the loom, with a new motor, it worked wonderfully. The final scarf is as below:

This was an amazing event, and taught me lots about the loom. I have several upgrades planned for the loom, but before I start on those I need to take some better pictures and video for here and YouTube.

This was an amazing event, and taught me lots about the loom. I have several upgrades planned for the loom, but before I start on those I need to take some better pictures and video for here and YouTube.

One of the flattering things was that a few people asked if they could buy one of the scarves. Since it was the first outing of the loom I declined that – I kept the first and last of the event, and gave two to members of the MINDSTORMS booth.