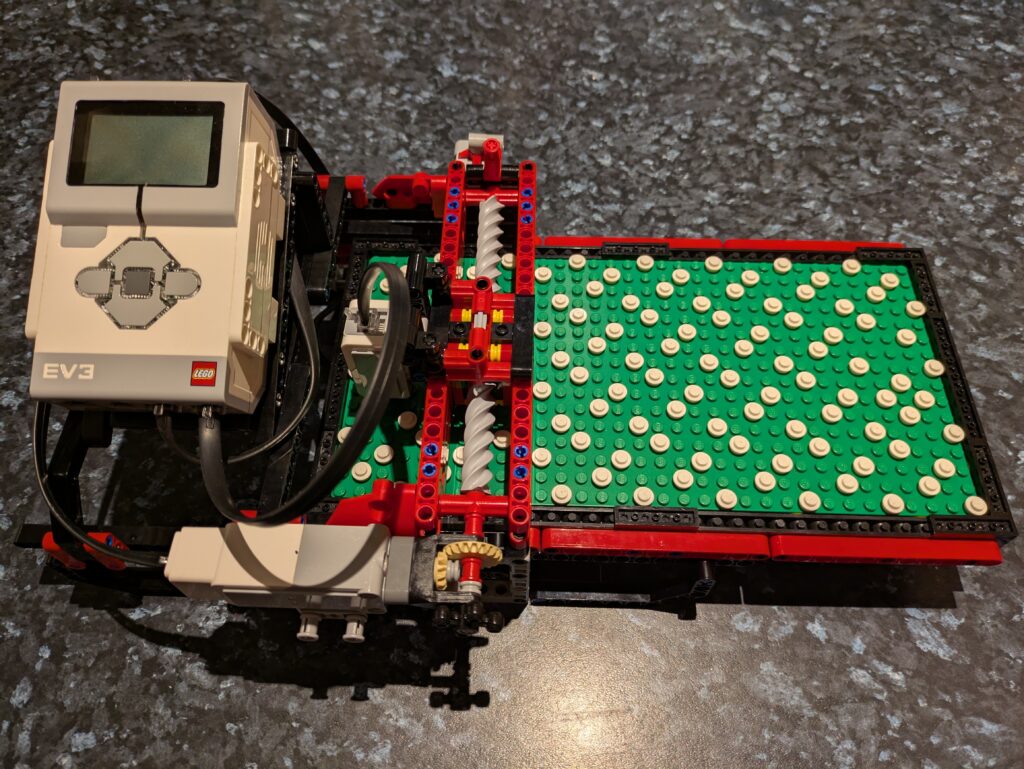

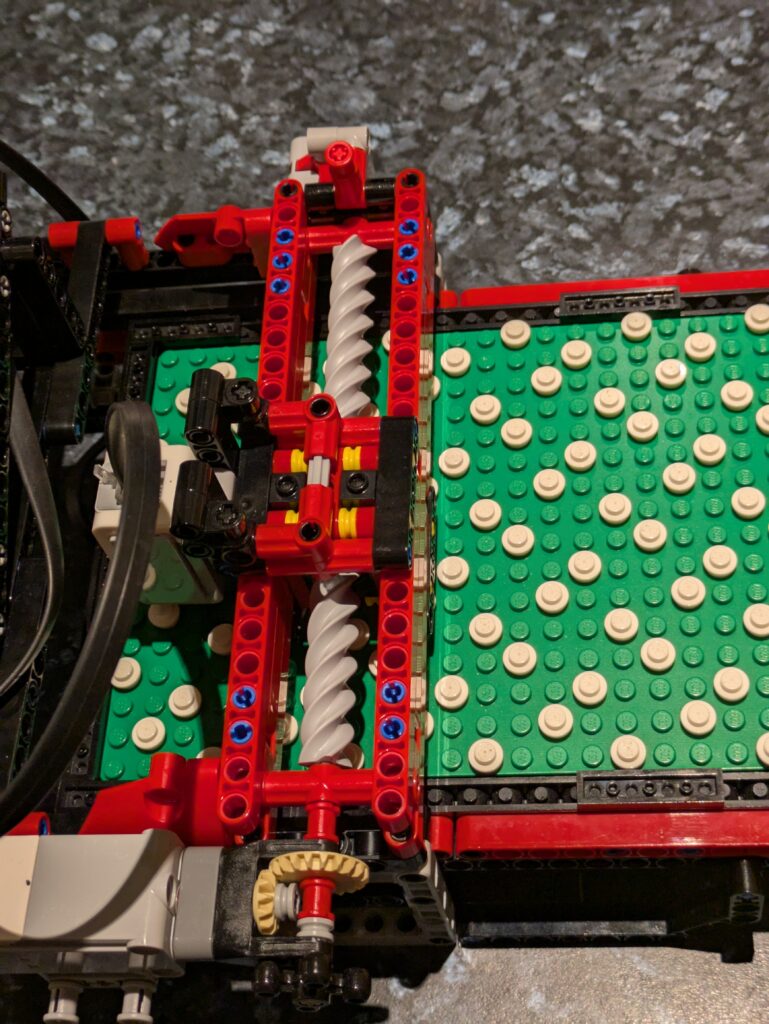

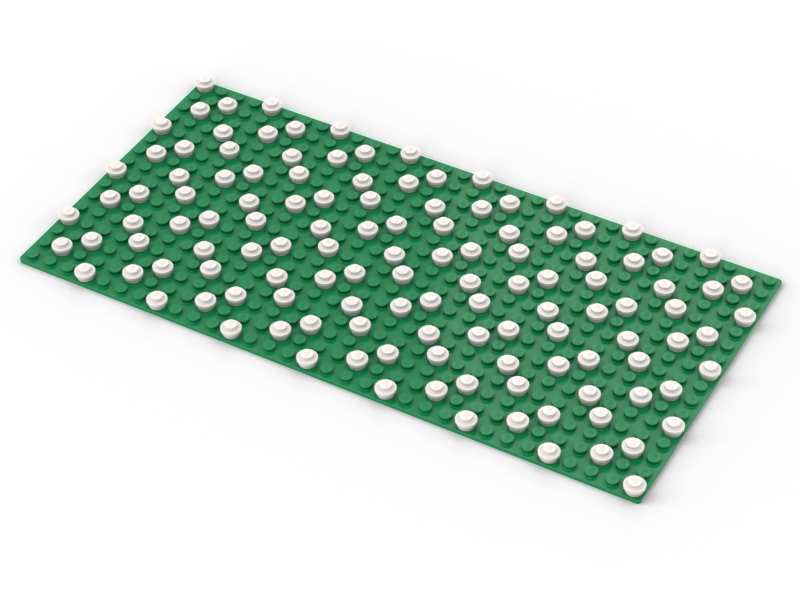

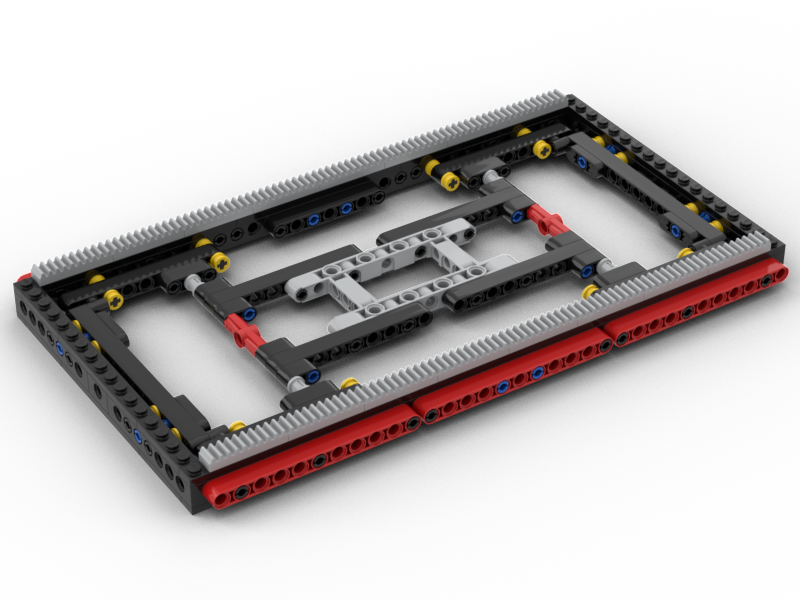

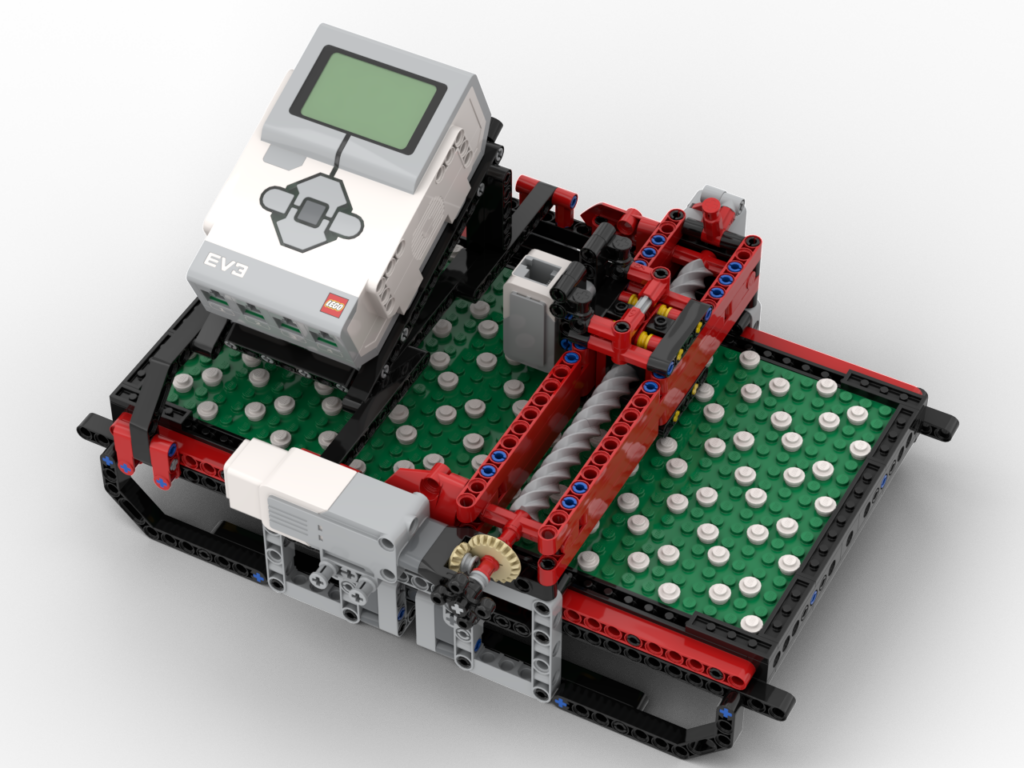

My redesign of the pattern board scanner part of my loom is basically complete. As it currently stands it’s a standalone scanner. It works ! It’s much faster than the old system and is really clean in its operation. I need to retrofit the new code into the loom controller code, which I’ll do in a few days’ time. Before that I want to deal with how the unit will sit on top of the loom, so I need to put the loom back into its operating state and get thinking.

Releasing the BIs and Code

Since this is working as a standalone device, and I’ve posted about it a couple of times on Facebook:

https://www.facebook.com/groups/legomindstorms/posts/3121354191346119

https://www.facebook.com/groups/legomindstorms/posts/3125960860885452

I’m, as usual, going to post the BIs and code for public use. I’m licensing them under the Creative Commons Attribution-NonCommercial-Sharealike 4.0 International licence CC-BY-NC-SA 4.0

The BIs are here: https://jander.me.uk/LEGO/resources/Scann3r.pdf

The EV3g code is here: https://jander.me.uk/LEGO/resources/Scann3r.ev3

There are no cables in the BIs – they’re a pain to route so I’ve left them out. The cabling ports and cable lengths are in the BIs. Routing them is left as as challenge to the builder 😉

The code will scan a board showing the dots as it goes, then clear the screen, and reshow the code from the scanned data. This can then be used as a base for something else.